news

73P Mic Preamp Design Log October 24, 2023 13:41

In 2018, I published a post about a “Mystery Project” that involved researching, building up, and listening to various circuits from vintage Neve consoles. In the five years since then, that project has evolved into a 500-series mic preamp kit, coming in early 2024. What follows is a preview of the “Design Notes” that will accompany the kit.

Picking a Circuit

Our intention with this project was to recreate the mic preamp from the 1073 preamp/EQ module as authentically as possible. (Neve actually had their own module with just the mic preamp called the 1290. But since 1073 is the model most people are familiar with, we’ll call it that.) In surveying the current field of 1073-esque preamps, we noticed two distinct approaches; we’ll call these the “three-stage” and “two-stage” designs.

The original 1073 (and 1290) used three stages. This approach uses two high-gain preamp stages (yes, I know it’s confusing for a preamp to contain preamps, but that’s what they’re called), and one low-gain output stage. Neve split the gain between stages this way to keep distortion consistently low at all gain settings. Most modern clones are three-stage preamps.

The two-stage approach has only one preamp stage, followed by the output stage. This is based on yet another Neve module, the 1272 line amplifier. Around the 90’s people started racking these modules and adding gain switches to convert them into mic preamps. Since then, several companies have made two-stage preamps, often named after the 1073 even though they are closer to the 1272. These can still sound great, and some are highly regarded.

The two-stage approach is appealing because it reduces cost and complexity. This is especially true for a 500-series module and DIY kit. However, after researching the circuit and evaluating a vintage 1272, we decided against it. In addition to being more faithful to the 1073, the three-stage design allows for more gain and better performance.

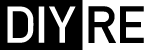

The preamplifier circuit, of which there are two in the 1073 and one in the 1272.

This is clear if we look at the original modules. The 1073 provided up to 80dB of gain, the 1272 only 50dB. From 0-50dB the preamps are identical, but from 55-80dB, the 1073 engages the third amplifier stage. Modern, two-stage preamps achieve more than 50dB by increasing the gain of each stage. This pushes the amplifiers beyond what they were asked to do in the original designs. This isn’t necessarily a bad thing, but it’s not how Neve designed their mic preamps. It’s telling that Neve never used the 1272 as a mic preamp, and instead went to the expense of the third stage. For this reason we decided that the three-stage design was the clear choice.

Adapting to 500-Series

The first challenge was how to fit the 1290’s many parts, including two big transformers and one giant transistor and heatsink. However, this was a straightforward problem that just required some grunt work. We also aimed to replicate the grounding scheme of the original. Neve managed ground currents carefully between amplifier stages to keep noise low. We recreated this on the 500-series module by giving each stage its own ground pour, which is tied to the others via a bus wire which runs along the bottom of the module back to the card-edge connector.

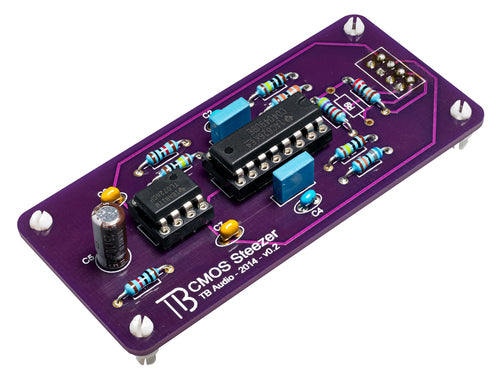

Our most recent prototype, with everything fitting in a single 500-series slot. We have at least one more round of prototyping to go, with an improved layout and the TIP3055 transistor.

The more complex problem was how to handle the power supply. The 80-series consoles ran on a unipolar 25v power supply. The 500-series on the other hand uses a bipolar +/-16v supply. Therefore, some form of conversion needs to happen to power the 1290 correctly from the 500-series rack.

We considered several options. First, we looked into adjusting the 1290 circuit to run on +/-16v. A bipolar +/-16v supply can also be used as a unipolar 32v supply by treating -16v as ground. In this scheme, some resistor values would just have to be adjusted to make the transistors bias correctly. This has the benefit that no regulation or DC-DC conversion is required, and some high-end 1290-style preamps have used this approach. However, we quickly realized that scaling the bias resistors would also require scaling gain setting and feedback resistors, which would in turn require scaling capacitors, and so on until the circuit barely resembled the original.

The next approach was to regulate both power rails down from +/-16v to +/-12v, thereby creating 24v between the two rails. This is the most common route taken by existing clones. It has the drawback of requiring two regulators or an integrated DC-DC converter, but it does not require any changes to the 1290 circuit.

We were set on this path when we realized that we could also achieve 24v with a single regulator, by using -16v as ground and regulating +16v down to +8v. This freed up some precious PCB space and eliminated a potential failure point. So we decided on this scheme, but with an important twist: we “deregulated” the +8v rail to get even closer to the original.

The Sound of the Power Supply

An overlooked aspect of the original console is the design and performance of the power supply. Nothing in analog audio is truly “outside the signal path.” Everything in a piece of gear from the chassis to the power supply affects the sound. The power supply affects audio in two ways: by being quiet or noisy, and by being “stiff” or “saggy.” The first is straightforward—we want to keep noise as low as possible. The second describes the supply’s ability to deliver current while keeping the voltage stable. A “stiff” power supply never drops below its rated voltage. A “saggy” power supply will momentarily drop below the rated voltage when faced with a big spike in the demand for current. These spikes come from especially loud, low-end-heavy sources and increase with gain and level. The sag creates distortion and compression which are part of the sound of the preamp.

Modern regulator chips and DC-DC converters are invariably as stiff as possible. So in order to recreate the sag of the 80-series power supply, we simply used the same regulator technology Neve used. Our +8v rail is generated utilizing a zener shunt regulator with a large pass transistor. Think of it this way: if you had a vintage 80-series console, would you replace the power supply with a modern one?

Selecting Parts

Transformers were the most straightforward component to choose. Carnhill transformers are the de facto standard for anything vintage Neve. The blue input and red output transformers have even become visually iconic in their own right. We tested some options from OEP, Sowter, and Ed Anderson, but found no reason to deviate from the Carnhills.

All of the transistors we auditioned for the 73P.

Transistors do the work of amplifying the signal. The 1290 card uses two types: eight small-signal transistors, and one power transistor to drive the output transformer.

Our process for choosing them was to compare several currently-available options to a vintage set taken from an 80-series console. These were BC109C for the small-signal, and a Newmarket 2N3055 for the output.

Our takeaway was that transistors are important to the sound, but only when they are saturating. That is, when the preamp was delivering a clean signal with no noticeable saturation, we heard little-to-no difference between the transistors. But once they started to clip, audible differences did emerge.

However, even in saturation the differences are not night-and-day. We’re talking about the kind of differences that can only be positively identified with good monitoring and careful flipping back and forth between samples. This is confirmed by Neve’s own approach. When they were making the 80-series consoles, Neve used various small-signal transistors, including the BC107C, BC109C, BC184L, BC184C, BC114 and various brands of 2N3055. Additionally, manufacturing tolerances were much looser in those days, so batches of the same transistor might be as different as one transistor was to another. The takeaway, however, is not that every 80-series module sounded significantly different. Rather, it’s that the circuit is designed to be highly forgiving so that almost any transistor can drop in and sound basically right.

Many of the transistors Neve used are still in production, including the BC107/BC109, BC184, and 2N3055. However, manufacturing processes have changed so much since then that there’s no guarantee that these would sound anything like their vintage counterparts. So we also tested several other transistors that have been used in this circuit, including the BC550, BC548, 2N4401, MPSA06, MPSA18 for small-signal and the TIP3055 for output. We spent several days exclusively listening to transistors on various samples and at various gain levels deciding on the BC109C and TIP3055.

Capacitors often get a bad rap as something to avoid in audio circuits (have you ever seen “capacitorless signal path” in ad copy?), but they are key to the sound of this circuit. The 1290 uses three types: polystyrene, tantalum, and aluminum electrolytic.

We know from our listening tests for previous designs that polystyrenes and tantalums have their own sounds which cannot be achieved with more modern options. As such, we didn’t consider replacing them.

Electrolytic capacitors required a deeper dive. In our experience, different manufacturers, series, and even voltage ratings of the same value electrolytic capacitor can sound different. So we wanted to make sure to do our due diligence on this front.

The main difficulty lay in finding a gold standard to measure against. Electrolytic capacitors have a shorter shelf life than polystyrene and tantalum, so any that could be pulled out of an 80-series console would have long gone bad or at least changed their performance too much to be a gold standard. Additionally, any consoles still in use have been recapped (had the electrolytic capacitors replaced) several times. This further complicates the search for a gold standard. That is, should the reference point the caps that “Rumours” passed through in 1977 or the ones that recorded “Nevermind” in 1991?

So the best we could do is to trust the techs who have been recapping these consoles for years. They generally recommend the BC 031 series for both sound and form-factor. So we compared a set of 031s against our favorite Panasonic FR series on the same BA283 card. The result was that we found the FR series to be practically indistinguishable from the 031. Based on this, we opted for the FR series as the radial (vertical) mounting style fits better in the 500-series space constraints.

Coming Soon: The 73P Preamp Kit

As you can tell by this point, we’ve come a long way with this project and are just putting on the finishing touches. We plan to release the 73P Mic Preamp in early 2024. The exact details, including pricing and launch date will be announced this winter. Please subscribe to our newsletter via the footer below to find out immediately when the kit is ready to order. And thank you for following along!

Sonic Varnish July 19, 2022 11:22

Editors note: the following is an article written by Allen Farmelo. This article made a big impact on me when I first read it about 10 years ago, and it certainly played a role in inspiring the Colour Format. It's since disappeared from the internet, so I'm very happy to be able to re-post it here with the author's permission. - Peterson

When I was about ten years old my father drove an old-school Mercedes with a wooden dashboard that I thought was one of the most beautiful things in the world. Its glassy finish fascinated me because I could see every detail of the wood grain. I asked my father how it got like that and he explained varnishing to me, claiming that “Mercedes probably put at least twenty coats on.” Not long after that I bought an old skateboard that was horribly beat up, and I told my father that I wanted to varnish it to look like the Mercedes dashboard. Down in the basement we stripped the nasty paint off that wooden skateboard and started applying thin layer after thin layer of varnish with careful wet sanding and cleaning between each one. It was taking forever, and after twelve coats I proclaimed that the skateboard was done. It was glossy – not quite glassy – and I’d certainly learned about varnishing. It’s a lot of subtle work, and no one layer really seems to do all that much.

Harmonic Distortion is Sonic Varnish

Today when people ask me how I achieved certain sounds in the records I work on, I struggle to answer the question because it’s such a multi-faceted thing. Then it occurred to me that you could think of it like applying many small layers of varnish, except that instead of applying clear-coats of lacquer I apply layers of very subtle harmonic distortion. The word ‘distortion’ here is nothing like the overdrive and fuzz we talk about when discussing guitar pedals and amps. In fact, most people with untrained ears can’t hear a single layer of truly subtle harmonic distortion because it only gently changes the sound, and sometimes it’s so subtle that it’s basically inaudible.

All audio equipment (including most plug-ins) imparts a small percentage of harmonic distortion, and this percentage is called total harmonic distortion, or THD. THD can be understood as the amount of extra sound generated by the electronics in the piece of equipment itself. Some audio gear is sought solely for the character of its harmonic distortion and is said to be very “musical,’ meaning that we humans tend to like how thing sound when it goes through these circuits. Equipment famous for harmonic distortion includes Neve preamps, Fairchild compressors and Pultec EQs. These are units that people will run sounds through just to pick up harmonic distortion that the circuit generates even when it’s not particularly doing anything to the signal. We call it tone, vibe, mojo, fairy dust, goodness, sweetness, fatness, warmth, size, girth, a sonic halo and all kinds of other names, but what we’re basically describing is that subtle percentage of extra sound that the circuit adds to the signal. For this article I’m calling it sonic varnish.

It’s important to remember that most undeveloped ears wont be able to tell the difference between a sound going through a Pultec EQ set at neutral and a sound that isn’t. Over and over again I’ve inserted pieces of gear in and out of signal chains to show people the difference. If their ear is untrained, or still developing, they squint intently at the speakers for a bit then open their eyes, lean back in their chair and say, “I can’t really tell the difference.” Could I tell the difference between a Mercedes dashboard that had twenty-one coats of varnish as opposed to twenty? I’d probably squint at them and give up as well, but a professional wood worker might be able to see the difference. And – far more importantly – a pro will know which varnish to use, how to apply each coat, and which of those coats should be the last in order to achieve the desired result. It’s the same with sonic varnish. One layer doesn’t do all that much, but many layers add up to a finished sound that anyone can hear and say, “Yeah, that sounds really cool.”

Applying the Layers

I believe that one of the reasons we love the sound of records from the 60s and 70s so much is that the sounds were achieved by the (often unintentional) application of many subtle layers of harmonic distortion. Take a Beatles record like Sgt. Peppers recorded on 4-track – a classic example. I’m not sure of the historical accuracy of this explanation, but lets assume that Ringo’s drums were tracked early on. Then those drums were bounced back and forth between the four tracks of tape as they made room for further overdubs. For the sake of argument, let’s guess that Ringo’s drums made two bounces after they were tracked. Each time they bounced, they picked up the sound of the console’s electronics, the tape machine’s electronics and the sonic character of the tape itself. If you count each stage as a layer of varnish, that’s roughly seven layers (preamp, compressor, tape, preamp, tape, preamp, tape). Then you mix the record, which adds another layer, then master it, then play it on your home system (which will have a THD rating, too), and we’re somewhere in the realm of twelve layers of sonic varnish before you hear Ringo’s drums.

RINGO’S DRUMS

- Layer 1: mic

- Layer 2: console preamp

- Layer 3: compressor

- Layer 4: tape machine

- Layer 5 & 6: bounce 1 (console and tape)

- Layer 7 & 8: bounce 2 (console and tape)

- Layer 9 & 10: mix to mono tape (console and tape)

- Layer 11: mastering

- Layer 12: your home system

Now compare that to a modern home recording. Typically the signal is recorded into a consumer grade preamp, processed with a compressor plug-in and bounced to disc.

TYPICAL MODERN HOME RECORDING

- Layer 1: mic

- Layer 2: preamp

- Layer 3: plug-in compressor

- bounce

- Layer 4: your iPod

The way I see it, this signal has had two chances to receive a coat of sonic varnish. During the recording it hit the preamp and then the compressor plug-in to achieve a second layer. Someone with only two layers of consumer grade varnish will still want to make the most of the recorded sound, so she or he is likely going to try to make each of those two layers as thick as possible. I see this all the time, and a slew of common amateur techniques have evolved. What I see most of is way too much compression, double and triple tracking of parts to add dimension, and the use of distortion plug-ins for a lo-fi sound that is more often a final ditch effort at sounding interesting than an aesthetic choice. People will try anything to make those two or three layers as thick as possible.

The temptation to overuse any one of these stages is strong because the sound just isn’t going to pop out of the speakers if you’re doing subtle work. This lack of sonic excitement is confounded by the lower quality components in consumer grade equipment, too. When you start to overuse any of these layers you acquire obvious sonic artifacts that will change the nature of the source sound to such a degree that the characteristics of the processing itself can overtake the characteristics of the original sound. A kind of haze emerges between the sound and the listener, and when you multiply that by however many tracks you have in the mix, things can get downright foggy. I hear it all the time and the result is simply unremarkable. As my father will still tell you, thick layers of low-quality varnish look horrible. They don’t dry evenly, bubbles get trapped in the varnish, and brush strokes are often visible. Rather than showing off and accentuating the amazing colors, details and depth of the original wood, you end up seeing the varnish and the artifacts of its application. The exact same thing happens with thick layers of consumer grade sonic varnish. There’s no short cut. You want your skateboard to look like a Mercedes? Start layering. You want your mix to sound like a great classic album? Start layering.

Modern Varnish Mixtures

I use a combination of digital and analog gear to achieve my layers of sonic varnish, and I chose each layer very carefully to emphasize a particular quality in the sound that I think serves the artistic vision of the project. And I always have my eye on the final mix. For example, if I know I’m going to mix to tape, I have that in mind as I compress the vocal because I know the vocal will “sit down” a bit more once the mix has hit tape. As I apply each coat of sonic varnish, I have the next layers in mind so that I don’t apply any one layer too thickly. I’m interested in the cumulative result of many subtle layers. Let’s take a look at a particular vocal sound to get a sense of what I mean. This is from a very sparse record of which I’m particularly proud of the vocal sound:

- TRACKING

- Layer 1: Vintage Telefunken U47 (tube microphone)

- Layer 2: Chandler TG2 mic preamp

- Layer 3: Tube Tech CL-1B Compressor

- Layer 4: Cranesong HEDD converter (a touch of its Pentode processing)

- INDIVIDUAL TRACK PROCESSING DURING MIXING

- Layer 5: API 550a EQ

- Layer 6: Tube Tech CL-1B hardware compressor

- FULL MIX PROCESSING

- Layer 7: API 2500 stereo bus compressor

- Layer 8: Dangerous Audio BAX EQ

- Layer 9: Studer A-80 1/2″ tape recorder

- ANALOG TO DIGITAL PROCESSING

- Layer 10: Studer output stage

- Layer 11: Cranesong HEDD A-D conversion (with a touch of Pentode processing)

Each and every one of these eleven layers is doing something so subtle that very few people can really hear the difference. But, each and every one is just as important to the overall sound as the one before it or the one after it. Use a different mic and the sound will change. Use a different preamp and the sound will change. Use a different converter into the DAW and the sound will change. Use a different bus compressor or tape machine and the sound will change. Each and every layer is equally important, while no single layer is all that important on its own.

My personal theory about why this technique works is that you’re never letting a single piece of gear overtake the original sound. Instead, you’re letting each piece of gear impart just a little bit of harmonic distortion – a little mojo, a small halo, a bit of warmth, a little extra size – and then moving on to the next piece of gear that’s going to impart another kind of harmonic distortion. Maybe the preamp warms up the mic a bit, and maybe the compressor puts a little halo around things, and maybe the tape machine adds a certain depth, and maybe the converter adds a little something-something. Layer by layer the varnish becomes thicker while each layer remains relatively transparent. The original sound is still in tact, but it has acquired all of these wonderful, subtle qualities along the way.

Gain Staging – The Craft of Varnishing

With wood, layers of varnish go on rather simply, one at a time, but there is still a craft to it. My coats of varnish on that skateboard weren’t nearly as well applied as my fathers because he had years and years of experience with a brush in his hand. He had the craft that told him how far to dip the brush, how hard to push that brush against the edge of the can to remove excess varnish, where to begin and end his strokes and how hard to push as he made them, and he knew when enough was enough. He knew how to varnish.

In audio, how you varnish is called gain staging. Gain staging refers to the rather complex craft of knowing where the optimal (or intentionally not optimal) operating levels are for any piece of gear in the signal path. How much signal you feed into a piece of equipment will elicit a certain amount and kind of harmonic distortion out of that circuit. Whether it’s tubes, tape, solid state or even a digital plug-in, the way you set the gain will determine the sound. To make matters more complicated, the way one gain stage is behaving will effect how the next one behaves in real time. Add to this that many pieces of gear can be calibrated to different levels, and that every sound you record is going to change how the gear is going to react, and you start to see the endless complexity. Gain staging is not trying to hit a moving target; it’s trying to hit a moving target from a rotating platform on the back of a speeding pickup truck on a hilly, winding road.

Developing Your Brush Stroke

So how do you learn how to gain stage properly? Practice, practice, practice and get great teachers who can guide you. It took me years to know how to get a good, solid signal happening with just a pre amp, more years to learn how to send that signal to a compressor properly, and more to learn how to get a tape machine to react the way I wanted it to. And I’m still learning all the time. My aim in writing this essay isn’t to pretend to be able to teach you how to do gain staging – how do I know which target you’re shooting from which pickup truck on which road? My aim is to stress that as you apply sonic varnish you need to really be aware of how you’re applying the layers.

My best suggestion is that you begin by simply considering the concept of sonic varnish when you’re making a recording and start to train your ear to hear subtler and subtler layers of harmonic distortion. And if you’re using a DAW to do recording, you can try to emulate more and more stages of sonic varnish using plug-ins. Believe me, it’s not a great idea to stack up a bunch of the same plug-in and expect them to do what a vast combination of great hardware and software can do together. Nor can you expect too much out of consumer grade gear. (Yes, the signal path I describe above costs thousands of dollars, and I don’t expect everyone to have access to that kind of gear). But, you can learn a lot by trying different things in the box. Here are some ideas:

- Use a plug-in that emulates analog gear (a compressor, an eq or other will be fine) to try to put a tiny halo on a guitar sound, or a little girth into a bass sound, or a bit of sweetness into a vocal. Don’t try to engage much of the processing – only enough to apply the smallest amount of harmonic distortion you can hear. Work in very very small increments and see what you can hear.

- Try using a few different plug-ins to achieve subtle harmonic changes in the sound without changing the essential nature of the original sound. See if you can get the sound to come to life while sounding just the same.

- Try to get 3db of compression out of two compressors doing 1.5db each. Then try three doing 1db each.

- Try remixing something you know you’ve put a few big layers of varnish on and see if you can achieve a less hazy result with more sonic impact by using more subtle layers.

In other words, take the concept of sonic varnish and experiment with it. There are really no hard and fast rules to follow, but hopefully the concept of sonic varnish will help you have a general guiding principle to follow. I’m sure you’ll come up with all kinds of ways to play with the concept.

What About Sonic Paint? – I need to recognize that there are many times when one is going to want to slam the hell out of something with a compressor, or distort something to the point where you can’t tell what it is, or eq something so drastically that its very nature is transformed. That’s not varnish – that’s paint. However, remember that most paints also need to be applied with great skill and are typically finished with a few very thin layers of clear varnish in order to add depth and brilliance to the color beneath. So, even if you’re going to slam a sound against a wall until it bleeds, those gaping, bloody wounds will be all the more gory if you can get a few coats of varnish on there to show it all off.

What About Lo-Fi? – Everything I’m saying would apply to achieving lo-fi sounds. If you’re interested in making a lo-fi recording, one of the most important things you can take away from this essay is that multiple layers of distortion will get you better results than one single lo-fi distortion layer. Some of my favorite lo-fi recordings are by Guided by Voices on four track recorders that imparted a lot of THD, but they also bounced their tracks back and forth quite a bit, layering the sounds and slowly degenerating the original sound. Compare that approach to sticking a distortion plug-in on a single digital track and most people will agree that the vibe is with the layered approach. Also, no matter how distorted a lo-fi record is, the layered approach will allow the original signal to acquire its new vibe and sound in lighter layers that will allow the original sound to maintain its character.

What about Genre Specific Sounds? – Absolutely work toward the aesthetics of the genre you’re working in, but keep in mind that in any genre the concept of sonic varnish will help to achieve great sounds. Techno may be a genre where digital sources never leave the computer, but even the sampled sounds will go through multiple manipulations to come to their finished luster, and many subtle layers will often serve that goal well. Black Metal may want to achieve an endlessly muddy distortion, but any guitar player will tell you that the pickup, the amp, the speaker, the mic, the preamp and the rest of the recording chain all go into making those sounds. Again, trying to achieve that sound in one or two small stages isn’t going to get the pro results. Extend the logic to any genre and I think the concept of sonic varnish will still prove a useful guiding principle.

What about Honest Recordings? – Classical and jazz recordists often talk of transparency and of “honest recording,” but the very fact that THD is present in every piece of gear makes “honest recording” a myth. Perhaps using fewer layers of sonic varnish will help keep the original recorded signal less tainted, but I think its important to keep in mind that the original recorded signal just passed through a rather tiny diaphragm or ribbon and became wiggling electron waves in a long thin piece of metal called a cable. To think of a recorded sound the way we think of a live sound isn’t going to help one grapple with what it takes to make a recording appear natural when it comes out of two speakers. More often than not, subtle harmonic distortion has helped me render sounds more honestly because the recorded sound can take on an added complexity, richness and 3D quality that got lost in the act of capturing it. The tendency in making these “honest recordings” is often to try to apply as little varnish as possible, but the counter-intuitive move of adding more harmonic complexity might bring the sounds of the instruments to life in ways that the thinner layers might not be capable of. As always, experiment and see what works for you.

It’s a Concept – Sonic varnish is a concept, a guiding principle, an idea. It’s something to have in mind when you’re recording and mixing that can help keep the bigger picture in focus. There are so many stages to recording, and no single one of them is any more or less important than another. As technology changes faster and faster our tools are going to change as well, yet our methods for recording seem to stay more or less the same. We still have to put a mic somewhere near a source, amplify it, get it onto a medium of some kind, then take that recorded sound and process it in some way in preparation for it’s final format. No matter how careful you are, you’ll be introducing some level of harmonic distortion at every stage, so it’s good to be aware of it. Even better to really know how to apply that harmonic distortion in a way that’ll get you the sounds your after.

Designing a Rack Mount Colour Unit Pt. 4 (Video) June 18, 2020 11:36

3 Quick Tips to Improve Your Soldering February 21, 2020 15:19

In the course of answering support emails, we see the good, the bad, and the ugly.

These three rules are the ones I tell beginners over and over again:

- Clean the tip more than you think you need to

- Heat the pad longer before adding solder

- Use less solder

Keep these in mind your soldering will improve by leaps and bounds.

The Top 5 Best Looking Pieces of Outboard Gear February 21, 2020 15:17

My top 5 favorite-looking pieces of outboard gear in no particular order (except for #1).

Designing a Rack Mount Colour Unit Pt. 3 (Video) January 23, 2020 13:19

How a Passive Direct Input Box Works December 15, 2019 00:00

If you’ve spent even a little bit of time in a recording studio or doing live sound, you’ve undoubtedly worked with a DI box. But what, exactly, do these little boxes do and why do we need them? In other words, why can’t you plug a guitar right into a mixing board or audio interface?

DI Basics

A direct input box is used when we want to connect an unbalanced, instrument output to a balanced, microphone preamp input. The most common scenarios for this are plugging bass and keyboards into the mixing board for live sound, or recording bass and guitar through mic preamps in the studio. DIs almost always have these features:

- Unbalanced, ¼” input

- Balanced, XLR output

There are two types of DI boxes: active and passive. Active DIs run on DC power, usually from the +48v phantom power from the preamp connected to the output, because they feature active components like transistors and integrated circuits. Passive DIs, the kind we’re talking about here, require no power and feature only a couple passive components.

The Problems

DI boxes were created to solve a particular set of problems that arise when connecting instruments to pro-audio equipment.

One of the first things you learn (very often the hard way) is you can’t just plug anything anywhere. The most obvious and dangerous example of this is shown below.

But why not? Incompatibilities come down to three main things:

- Voltage

- Impedance

- Grounding

In the case above the answer is obvious: voltage. If you plug your guitar directly into the wall, the guitar will be hit with 120v mains power and something will explode or melt. In most cases the differences aren’t so obvious, but they’re just as real.

The Solution

What makes passive DI boxes so elegant and simple is that they utilize a single component to solve all these problems: a transformer. A transformer is a large, primitive analog component that ought to be obsolete except for the fact that it can do several things at once all while sounding great.

A transformer’s construction is very simple: it’s a single magnet with two wires wrapped around a metal core. The wires themselves do not touch each other, yet signal transfers between them through the principle of electro-magnetism. That is, an alternating current (which in this case carries audio signal) in the first wire generates a magnetic field in the core, which in turn generates a corresponding current in the second wire. These wires are called the primary and secondary windings. In the following sections we’ll see how this simple component can do so many things by showing how it solves the three problems we identified above.

Voltage

Instrument output levels span a very wide range from the millivolts up to ~10 volts. Preamp input stages, on the other hand, are optimized for the very low output levels of microphones, which rarely exceed the millivolt range. So the transformer must solve the problem of too much voltage.

The coils in a transformer have specified number of “turns” around the core, and the ratio between the turns of each coil is the most important feature of any transformer. This is because a transformer reduces or increases the voltage of a signal in direct proportion to the turns ratio. That is, if the primary coil has 200 turns and the secondary has 100, the turns ratio is 2:1, and the voltage induced in the secondary will be half of that in the primary. The standard turns ratio for a DI transformer is 12:1, so the output is always 12 times lower (-21.5dB) than the input. Now the mic preamp is happy and won’t be overdriven by the instrument’s output voltage.

Impedance

Every device has its own inherent input and output impedance. Without going too deep into the wormhole of explaining the concept of impedance, it’s important to know one general rule of thumb: when connecting two audio devices, the input impedance should be at least 10x the output impedance. When this rule isn’t followed, things start to sound muddy, noisy, and distorted.

So for example, the output z of a dynamic microphone is around 250 Ohms. This is why the input impedance of mic preamps is usually at least 2.5k Ohms. Similarly, guitars usually have an output z of between 10k-100k Ohms, so guitar amp input z is usually 1M Ohms. Now look what happens if we connect a guitar directly to a mic preamp: the output z is significantly higher the input z.

In the same way that our transformer induces a different voltage across the secondary than the primary coil, it also transforms impedances. But whereas voltage is transformed in direct proportion to the turns ratio, impedance changes by the square of the turns ratio. Thus, the impedance ratio for our 12:1 transformer is 144:1.

Say we are hooking up a guitar with a 20k Ohm output impedance to a mixing board with a 2.5k Ohm input impedance for the mic preamps. The transformer divides the 20k output z by 144, giving us an effective output z of 138 Ohms. Now we are nicely in the range of our rule of thumb; the input z of 2.5k is at least 10x higher than the output z of 138. (You can also run the math the other way: the transformer multiplies the 2.5k input z by 144, giving us an effective input z of 360k, which is more than 10x greater than 20k.) Now we can be confident that the full signal will pass from the guitar to the console without distortion or other artifacts.

Grounding

There’s a great saying that “all electrons want is to go to the ground and die.” This is a way of expressing that current always flows from high voltage to lower, and the ground is our 0 volts reference point. This is why the safety pin of the outlets in your house are wired to a pipe in the ground (check your basement!)—it gives electrons a quicker path to the ground than through your body. However not all “grounds” are a perfect 0 vots, and ground problems arise when two connected pieces of equipment have different ground voltages or when noise doesn’t have a quick path to ground without infecting the audio circuitry. These are the main causes of hum and buzz in the studio and live sound.

Pro-audio equipment addresses ground problems by using 3-pin, balanced connections where the ground and audio paths are separated. In a standard XLR cable, for example, pin 1 is ground (also known as “chass) and pins 2 and 3 are signal + and -, respectively. A well-wired studio with only balanced connections can be practically free of ground noise.

Instruments, however, use 2-pin, unbalanced connections which do not allow for isolating the ground and signal. In a standard ¼” guitar cable, for example, the tip carries the signal, while the sleeve carries the ground.

So what happens if we plug an unbalanced guitar directly into a balanced input? As you can see in the illustration below, the sleeve of the unbalanced guitar cable will connect to both the chassis and signal - parts of the balanced input. This provides a path for current to flow between the ground of the unbalanced system and the signal - of the balanced system, in other words noise, hum, and buzz.

Modified and reused under the Creative Commons Attribution-Share Alike 3.0 license.Original rendering by Søren Peo Pedersen

Transformers solve this problem by providing what's called galvanic isolation between the input and output stages. Recall that transformers transfer voltage from one winding to the next through electromagnetic induction, without providing a path for current to flow. Thus, they allow the balanced output stage to communicate the signal to the unbalanced input stage without allowing ground currents to form. That's it. An elegant solution to a complex problem.

Designing a Rack Mount Preamp with Colour Pt. 2 (Video) December 7, 2018 17:54

Back in April when I announced that I was working on rack mount mic preamp kit, I was unsure of the direction to take. So I posed the question to you, the DIY community: should I design a 2-channel preamp with more features, or a 4-channel with fewer features?

Your answers was resoundingly in favor of the 2-channel version. So I went back to the bench full of clarity and purpose to prototype features and lay out the circuit boards. Today I'm excited to show you my progress so far and ask you for some final bits of feedback before I finalize the circuit and front panel.

The rough front panel layout (click to expand)

As you can see in the rough front panel layout above, our rack mount unit has grown to be much more than just a stereo mic preamp. In fact, with the line input option, it's more like our CP5 Mic Preamp and Colour Palette combined, with a couple extra features.

So what do you think of the feature set?

Is there anything you'd absolutely love to see that I haven't included?

Is there anything I've included that seems superfluous?

Thanks in advance for your feedback!

Mystery Project: The Basics of Vintage Neve Circuitry August 29, 2018 09:17

I'm just beginning a new project and I thought I'd try something different this time: I'm going to make the entire design process public. That means I'm going to share everything I learn as I go and I'll publish my design files under an open source Creative Commons Share-Alike license.

Choosing the Project

I titled this post "Mystery Project" because right now it's a mystery to me. The project will be some sort of Neve-inspired kit, but that's all I know.

"Neve" refers to a family of analog audio gear, either directly designed by or inspired by the designs of Rupert Neve. Neve's vintage consoles (especially those of the 70's as we'll see later) are famous for their "warm," "larger-than-life" sound. And a whole cottage industry has emerged around cloning parts of these consoles to make the "Neve sound" available for modern project studios that don't possess a console. The 1073 and 1084 preamp/equalizers and the 2254 and 33609 compressors are all console modules that have found a second life as plugins and pieces of standalone audio gear.

Neve 8048 Console. Photo by Neve Sweden [GFDL or CC BY-SA 3.0], from Wikimedia Commons

I emphasized "some sort of Neve-inspired kit" above because I have no idea what it will be. I know I want it to be something more unique than a straight clone. There are already a lot of great "British Console" projects out there from The Don Classics, Martin Adriaanse, and Audio Maintenance Limited, so I want to make sure that anything we do fits a niche not already filled by those folks.

The truth is I know very little about the Neve history and right now. So my immediate goal is to learn as much as I can with the hope that it will eventually lead to me to a cool, unique idea for a Neve-inspired kit.

Vintage Neve Basics

My first step was to invite my friend and Neve expert Jens Junkurth down from New York to school me on the circuitry. He gave me a day long crash course, some of which happened live on our Live Q&A on Youtube (archive). There were three big takeaways from that crash course:

1. There are only a few "classic" circuits. All of the myriad Neve clones and Neve-inspired devices are based on a very small collection of circuits the early 1970's. The 80-series consoles of this era featured the preamp/EQ modules that have become famous like the 1073, 1081, and 1084 as well as the 1290 preamp and 1272 bus amplifier. These circuits are all discrete and class-A. By the mid-70's Neve had switched to class-AB circuits and by the end of the 70's the consoles were all IC-based. So, for this project I'll be focused on a very small sliver of Neve's 50+ year history.

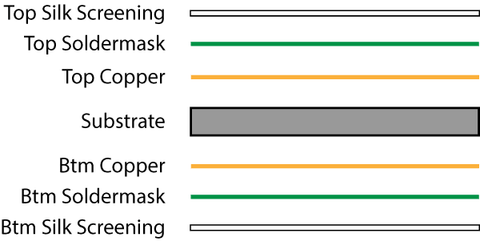

2. The circuits are quite simple. While the 80-series consoles are large and complex, they're built from just a few simple building blocks. These building blocks are small amplifier boards with the prefix BA, for "board amplifier." The most ubiquitous, the BA283, contains two sections: a preamp and an output driver. These two circuits are replicated dozens of times throughout a single console, making up the active parts of the mic preamp, equalizer, master section, etc. And both of these circuits contain only three transistors each. For a bit of perspective, the primitive 741 opamp contains 20 transistors.

The BA283 (6 transistors) vs. the 741 opamp (20 transistors)

3. It's all about the parts. Because the circuits are so simple, every part matters. And unfortunately, almost every part used in the originals is long obsolete. Various revisions and years of repairs also give rise to difficult questions about authenticity. For example, the first BA283s used BC184C transistors. However, Neve officially recommended BC107 and BC109 for repairs, which are arguably found in more classic consoles than the "originals." The same issue applies to capacitors. Like any other console, Neves must have their aluminum caps replaced every few years. So many classic albums featuring the "Neve sound" would not have been recorded with the original caps. Because of issues like these, I anticipate that sourcing will be the most challenging part of this project.

Next Steps

Phase 2 of this project is to build up some circuits and listen, listen, listen. I've started compiling a master bill of materials to collect all of the parts I've seen used in BA283 circuits.

I've also laid out the Preamp and Output amplifiers on two separate PCBs. I plan to order a few of each PCB and every part I can find to build up several different versions of each stage. Then I'll spend a few weeks tweaking and listening, to get a sense of which parts sound best together.

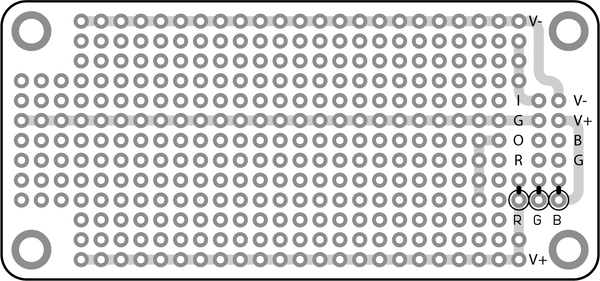

My first layouts of the BA283 Preamp and Output sections

Follow Along

I'm excited to keep digging into this project and to share my results with you. If you want to check out or use the design files for yourself, keep an eye on this Google Drive folder. The schematic and PCB files are for Diptrace, which you can download for free. You're welcome to use these files any way you like (under a Creative Commons ShareAlike license); however, keep in mind that these designs have not been tested yet! For all I know the boards won't be good for anything besides creating smoke.

Please stay tuned for the results of my first builds and listening tests next month. And in the meantime, I'd love to hear your thoughts, ideas, feedback, etc. in the comments.

Designing a Rack Mount Preamp with Colour Pt. 1 (Video) April 11, 2018 14:42

Now that we've wrapped up design on the OLA5 Opto Compressor, I can finally get back to a project I've been wanting to do for a long time: a multi-channel, rack-mounted mic preamp. The preamp will be use the same circuitry as our CP5 500-Series preamp with Colour but with some additional features.

I'm still in the early stages of this design, so I thought I'd share what I've got so far with you and solicit your feedback. I go into more detail in the video above, but basically I've prototyped four new features:

- Direct input

- LINE switch for running the CP5 in line-level mode

- Parallel, dry output

- Second Colour socket

We could fit all of these features in a 1U, two-channel box. But my big question for you is:

Should we do a 2-channel version with more features or a 4-channel version with fewer features?

I'd also love your feedback on the features I've worked on so far.

Designing an Authentic, DIY-friendly LA-4 Opto Cell February 7, 2018 14:35

Today we're debuting a new monthly video series called, "From the Bench." In these videos, I'll show you what we're working at the moment and talk a bit about the technical challenges of the design.

As you may have read, we've been working on the OLA5 Optical Compressor kit for almost a year now. The OLA5 will be a 500-series opto compressor based on the Urei LA4.

In fact, it shares the exact sidechain circuit as the LA4. But getting the sidechain just right has been one of the the biggest design challenges of the project. We've finally arrived at something we're really excited about, which I go through in detail in the video.

Designing a 500-series Optical Compressor pt. 2 December 20, 2017 18:07

Hey there, folks! It’s time to update everyone on the second collaboration between JC-diy and DIYRE, the OLA5 optical leveling amplifier for the 500-series modular format. After an initial post back in March we received a lot of useful feedback (thank you!) which we have taken into consideration as we worked toward a final product. - Joel Cameron, JC-DIY

As discussed in the first post, the objective of the OLA5 was to reproduce the unique, musical dynamic character of the classic “LA”-style optical leveling amplifiers we all know and love in a compact, DIY package, while updating its usefulness for the modern studio environment.

I started with the sidechain of the LA-4, but used an entirely updated, IC-based signal path, which allows folks who want to to ‘roll’ their own ICs for the sound they prefer. And like the EQP5 Passive Equalizer kit before it, the OLA5 is compatible with the optional Vintage Output kit, which includes a discrete opamp, a steel core output transformer and a NOS tantalum capacitor to add a bit of vintage flair to your leveling amp!

The most recent OLA5 front panel design

To Blend or not to blend?

This was the big question from my first post: were we going to give the OLA5 parallel functionality or not? There were differing and passionate opinions, though overwhelmingly people voted "yes"!

Nevertheless, I do understand many folks' hesitation to do so with such a classic sidechain. Arguably, parallel processing is more commonly used with heavy handed devices that crush and sometimes outright distort signals for blending with the unprocessed versions. As such, one might question the usefulness of this functionality on an “LA” style optical limiter, none of which are known for heavy-handed treatment of source material.

But the usefulness of this function is immediately apparent once you begin to put it to use. Hitting the limiter solidly and blending with the unprocessed signal can really stick a track where you want it dynamically, giving it more authority and simplifying mixing without evoking the feeling of having been processed at all. Perfect for uber-dynamic singers or for smoothing out an unevenly strummed acoustic guitar track. Beautiful.

But fear not, if you were one who preferred keeping the OLA5 a purely serial processor we have not abandoned you—it can be a purely serial processor as well. How? Its parallel functionality (with its corresponding summing stage) only comes into play when the “Mix” button is depressed (at which time the “Mix” knob becomes active). With this button switched out, the summing portion of the circuit is entirely removed from the signal path, leaving it a purely serial processor, just like the classics!

Let’s be Discrete: Rolling our own opto cells

The OLA5 differs not only from other DIY optical kits, but also from most every currently manufactured optical limiter in that it uses discrete optical gain cells. That is, optos made up of a discrete light source coupled with a separate light dependent resistor (LDR). Most every optical design currently available uses off-the-shelf optocouplers (which contain these two elements in a small, premanufactured, hermetically-sealed package with wire leads for soldering) made by companies like Vactrol and Luna (formerly Silonex).

The extremely fast response times of these opto-couplers are ideal for use with modern sidechains that provide control for time constants, and they can yield very musical, if rather transparent dynamic control. The classic LA-series of optical levelers, however, relied upon the time constants inherent to the LDR, providing engaging dynamic processing marked by a distinct, and beloved non-linear release characteristic. Try as I might I could not get any modern sidechain design I tinkered with to properly mimic this classic behavior in a convincing way. Ultimately, I decided that if it wasn’t broken I wasn’t gonna try to fix it—a discrete opto it must be!

Since the gain element is light-sensitive these optos need a dark environment to do their thing, so our concern became how best to provide light-tight enclosures for discrete optos on an otherwise ‘open’ 500-series pcb. Well, Peterson devised a devilishly simple and effective way to enclose each of the two opto cells, keeping them happily in the dark.

A cross section of our discrete opto design

A red LED (the light source) solders directly to the motherboard via a round spacer/riser with a diameter the same as the leading edge of the LDR, while the LDR solders to a small daughterboard that is then mounted (using screws) directly facing the LED. Acting as spacer between these two components is a black plastic tube which fits snugly around both the rim of the LDR and the spacer at the base of the LED, effectively cutting both devices off from the light of the outside world. This design is simple to assemble and works perfectly in a brightly lit room, so you can be certain it will work superbly when mounted within the interior darkness of your 500-series rack.

Compress or Limit?

In keeping with the spirit of the classic leveling amps the OLA5 offers a simple choice of either ‘compress’ or ‘limit’ functionality. The compress selection provides a roughly 2:1 ratio with a low threshold, great for general leveling. The ‘limit’ selection is user definable (via jumper on the main pcb) from two choices, both with a higher threshold setting. Use the pcb jumper to select your ideal ‘limit’ ratio, and then use the front panel pushbutton to select between compress and limit function in use. The build manual will provide resistor values for limit ratios of 4:1, 8:1, 12:1 and 20:1, so users will have choices of which two to include in their build.

More Features: Accurate metering, stereo link, and HPF

Metering of gain reduction on the OLA5 is provided via a 10-segement LED display with a -26dB range using TI’s LM3916 dot/bar driver IC. Unlike an analogue VU meter, this display is extremely fast, so reduction on attack transients (the attack is faster than you might think!) is accurately displayed as is the initial release followed by the slower, non-linear release. Ultimately, one chooses settings for a device like this by ear, but it’s still nice to see what’s really going on inside the thing!

Two OLA5s can be strapped for stereo use using the ‘link’ connectors provided on the back of many 500 racks. If your host rack doesn’t have link connectors you can make this connection directly between your two OLA5s with a single wire before mounting them in the rack. When you want the pair to track in stereo simply push the ‘link’ buttons on both units, while making sure to match other settings as well. With the ‘link’ switches out they are separate, mono processors.

And lastly, we have further expanded the usefulness of the OLA5 by giving its sidechain a simple and effective hi-pass filter. Simply engage this filter when you want to keep strong LF content from kicking up the leveling too much, yielding a beefier tonality to processed material. Great with parallel function for mixes and subgroups!

Onto Calibration – no jig required!

This is a another bit of cool that I’m really pleased with on the OLA5. Proper function requires calibration after the unit is built (metering and stereo tracking). One of my early concerns for doing a project like this was how to make it so people can calibrate it if they don’t have a test jig (a nifty little rig that plugs into the host rack and extends connections via wires/ribbon cable). I hated the idea of making people buy a test jig for the one, ever, time they calibrated their OLA5—what a waste of money. Once again Peterson, always the clever fellow, came to the rescue.

His solution was to mount the necessary trimpots 90-degrees off the pcbs, facing the front, sandwiched between the front panel controls and recessed below the plane of the faceplate. This way users can build the unit (sans faceplate), mount it in their 500 rack and have front access to the trimpots needed for calibration. After they finish calibrating, simply power down, pull the module, and attach the faceplate and knobs to officially complete the build. Done! (No special jig required! :)

And the calibration itself requires no special gear either. All you need is a flat-head precision screwdriver and a DAW with basic I/O and a signal generator plug-in capable of producting a 1kHz sine wave (and if, for whatever reason your DAW cannot produce this test tone a link to a downloadable WAV file of it will be included with your OLA5 kit).

The most recent OLA5 prototype

See You Next Year

So as you can see, we're very close to putting the finishing touches on this thing. All of the major circuit points have been ironed out and stress-tested and our prototype front panel came in looking great. All that's left is what we like to call "the final 99%": ordering parts, laying out the kit, making the assembly guide, etc.

If all goes well, we hope to announce a launch date and pricing in January. Thank you so much for following along and providing feedback during our design journey. We are so excited to get this kit into your studio!

Bumblebee Pro Active DI Kit Pre-Order Offer October 24, 2017 14:52

Longtime DIYRE followers will know that we go way back with Latvian designer Artur Fisher. We helped Artur launch his first product, the RM-5 ribbon mic, back in 2011, and our customers have been continually blown away by his designs since then.

So I'm proud to team up with Artur again to launch his new active DI kit, the Bb-D2.

Bb-D2 Design and Sound

The Bb-D2 is a premium direct box that reflects Artur's no-compromise design attitude. The active circuitry is all discrete, featuring matched JFETs, and the output transformer is a custom designed to compliment the active stage.

All of this sweating the details has resulted in a world-class DI that captures instruments with natural clarity and just a tiny bit of analog finesse. The JFET input stage ensures a high input impedance, making the DI great for high-Z sources such as passive guitar/bass pickups, Rhodes, and piezos.

Beginner Friendly Kit

Part of what makes our partnership work so well is that, like DIYRE, Artur is as serious about the DIY aspect of his products as he is about the design. The Bb-D2 kit comes with every part needed to build the DI and is accompanied by a step-by-step instruction guide. Also, after having handled many support tickets for his ribbon mics over the years together, I can tell you that Artur is very responsive to questions.

Introductory Offer

Artur is currently funding his first production run of Bb-D2s, so now is the best time to get in on special pre-order pricing. Until Wednesday, Nov 8 the full kit will be only 119 EUR (down from 169 EUR street) with the code DISCOPAMPDI.

Check out the pre-order page on Bumblebee Pro's site for full offer details and to place an order.

Colour Lineup Update August 2017 August 31, 2017 09:26

Recently we made full sample videos of every Colour module we have available so you can hear each at a few settings on a variety of sources. These samples give a nice accurate picture of what you’re getting with each Colour. However when I’m looking to buy anything that makes sound, there’s no replacement for seamless A/B audio samples, and switching back and forth between videos just doesn’t cut it for those purposes.

So we've taken our audio samples and put them back-to-back so you can hear every Colour at the same settings on a single source. Not only does this let you hear the overall character of every module, but it gives a good sense of which Colours are subtle even when pushed, versus others that start gnarly at low settings and collapse even more as you push them.

For a few highlights, check out how the bass comes alive with the 15IPS, or how the CTX adds a subtle weight to acoustic guitar at medium settings. The Distortastudio is an easy favorite for blowing up drums and electric guitar, while the Colourphone really sits the same electric guitar in a nice, brash, fuzzy place. Or check out how Pulse makes a great vintage slapback on drums. Check out the samples below:

"Explain Like I'm 5": Audio Transformers May 25, 2017 12:28

What are transformers?

Transformers are those huge, heavy, primitive-looking parts you’ll see in both vintage and modern audio gear.

They look something like this:

Or this:

Or this:

What do audio transformers do?

A lot of things! I guess that’s why we keep them around, primitive and expensive as they are.

Transformers do a lot of different jobs in audio gear, including:

- Stepping voltages up or down: increasing output level of microphones, bringing instruments down to mic level, etc.

- Providing balanced inputs and outputs

- Impedance matching

- Eliminating ground loops

- Blocking DC while passing audio signal

How do transformers work?

A transformer is just two long wires wrapped around one magnetic core. Signal passes from one wire to the other, but the wires don’t touch. What sorcery is this?! It’s a funny feature of our universe called “electromagnetism,” where electric current creates magnetic fields and vice versa.

Modified and reused under the GNU Free Documentation License

The electrical current running through first coil of wire (the “primary”) creates a magnetic field in the core. This magnetic field then induces a corresponding voltage in the second (“secondary”) coil. Voila! We now have the same signal at both sides of the transformer without a single electron making the journey from one side to the other.

How do transformers step voltages up or down?

We only get that same exact signal on both sides when both coils have the exact same number of turns around the core. By changing the number of turns in each coil, we can directly change how much signal is transferred between them.

For example, if the primary coil has 200 turns and the secondary has 100 turns (we call this a “turns ratio” of 2:1), only half the signal will be transferred. This is called a “step down” transformer. However, we could turn that same transformer around and use it as a “step up” transformer to double the signal!

If that sounds too good to be true (free gain!), it’s because we’ve only considered half of the equation—if a transformer steps up voltage, it steps down current by that same amount, and vice versa. Another way of saying this is that transformers can’t create or destroy power (power being the product of voltage and current). You could think of transformers as trading voltage for current, while power stays the same.

For example, let’s say a 1:2 transformer sees an input of 1 Volt at 1 amp current. At the secondary, the voltage will be stepped up to 2V, but with only 0.5 amp of current available. So a 1:2 transformer for voltage is a 2:1 transformer for current.

How do transformers match impedance?

Sometimes it’s important to match the impedance of two devices that are being connected (see "ELI5: Impedance" for more on that). For example, your guitar won't sound very good if you plug it right into a mic preamp—the output impedance of the guitar is just too high to transfer all its signal to the preamp. So we use a DI box to step the guitar’s output impedance down to mic level.

And guess what's in a passive DI box—a transformer! Transformers can step impedance up or down in the same way they do with voltage and current. Except whereas they change voltage by the turns ratio and current by the inverse of the turns ratio, they change impedance by the square of the turns ratio.

So let’s look at a DI box as an example. A typical passive DI box transformer has a turns ratio of 12:1, which means it will step down the guitar’s output impedance by 144:1 (12 squared). A typical output impedance for a single coil pickup is around 20k Ohms, which our DI box will step down to 138.8 Ohms, which is typical of a microphone. Now we can run that guitar directly into our mic preamp with no impedance issues. Transformers win!

Why do transformers sound so good?

Of course, we don’t just keep transformers around to do technical jobs—they also sound really good. There are a couple reasons for this, mostly having to do with the unique ways in which they "fail" to be perfectly clean and linear.

Like all analog components, transformers clip when given too much signal. Transformer clipping happens when the core saturates and can't contain any more magnetic flux. This sets a hard limit on the amount of signal the transformer can pass and generates harmonic distortion.

What makes transformer saturation so lovely is that the distortion it creates is inversely proportional to frequency. Which is a fancy way of saying transformers create more warm, gooey, low-frequency distortion and less harsh, bright, high-frequency distortion.

Transformers also exhibit another distortion phenomenon called "hysteresis." This is where the core, after getting magnetized by a signal, stays magnetized for a short period of time after the signal is removed. Hysteresis creates low-frequency, harmonic distortion at all signal levels, not just when the core is saturated. This same effect is a large part of the desirable sound of analog tape.

Why is transformer inductance important?

Inductance is a measure of how well a component converts voltage into magnetic flux. We're concerned with inductance in audio transformers because higher inductance in the primary coil translates to better low-frequency response. Inductance can be increased with either more windings or a more permeable core material (see below).

How does core composition affect the sound?

Different materials have different abilities to contain magnetic flux—this is called “permeability.” Core materials with higher permeability create higher primary inductance, and therefore better low-end response. However, more permeable core materials will also saturate faster than less permeable ones. Ah, nature, where everything's a tradeoff!

The most common core materials for audio transformers are M6 steel (steel with a bit of silicon) and nickel/iron alloys. Cores with high nickel content are more permeable and more expensive, with less hysteresis than steel cores.

In general, steel will have higher distortion at normal signal levels due to hysteresis, while nickel will have higher distortion at higher levels, due to saturation. For this reason, you'll often find high-nickel cores in high-quality transformers designed for lower signal levels, and steel cores in cheaper transformers or those designed for high signal levels.

What’s a zobel network?

Transformers, like all other parts that exist in the real world, have unintended effects called “parasitics”; ie, extra resistance, inductance, and capacitance that an ideal transformer would not have.

Sometimes these parasitics will combine to cause the transformer to ring in the audio range. That is, if fed a certain frequency, the transformer will keep ringing at that frequency even after the signal is removed.

A Zobel network is a simple, passive filter consisting of a resistor and capacitor placed after the transformer to eliminate ringing.

What'd I miss?

Thanks for reading! Let me know in the comments below if you have any questions about transformers I didn't answer.

Designing a 500-Series Optical Compressor Pt. 1 March 30, 2017 13:33

It’s time to let folks in on the next collaboration between JC-diy and DIYRE. Our first effort resulted in the EQP5 passive equalizer. This time around we’re doing a classic-style optical limiter.

I have always been a fan of the classic optical leveling amplifiers, and for good reason — their musical processing and simple functionality (just two knobs, one for reduction and the other for gain make-up) make it hard to produce bad results. The most famous leveling amps are the LA-2A and LA-3A from Teletronix (later Urei) which are lovely not only in the character of their dynamic processing but in the inherent tone of their signal paths. It has long been my desire to create a DIY-friendly project whose behavior evoked the spirit of these classics while being accessible in both cost and build, so now we’re making it happen!

We are tentatively calling it the OLA5 (for Optical Leveling Amplifier 500 series ).

So What is a “Leveling Amplifier” Anyway?

“Leveling Amplifier” is a name given to early optical compressor/limiters, as their intention was to level (average) a signal’s dynamic range to make it easier to balance in a mix. The gain reduction element in these designs used a voltage divider featuring a light-dependent resistor (LDR) driven by a light source (an electroluminescent panel or an LED) to drop the level of the signal being processed. As the intensity of the light source (driven by its sidechain amplifier) increases, the resistance of the LDR drops, causing a reduction in level. Because the reduction is produced by a passive device (a resistor) there tends to be less obvious distortion in optical compressors compared to other designs with active gain components.

Additionally, LDRs possess an inherently non-linear release characteristic which changes based on how hard they’re driven. Subtler processing yields soft, forgiving time constants, but wind them up a bit, and you’ll have plenty of grab followed by a fast initial release that slows as it gets closer to full release. This non-linear response gives these processors a unique and musical ‘leveling’ characteristic (as opposed to a more linear, VCA-based compression most of us are already quite familiar with). This characteristic is highly prized for its ability to flatter vocals, bass, and guitars in particular.

The LA-2A was a tube unit, and the LA-3A was all discrete solid state, and both had input and output transformers. By contrast, the later LA-4 was all IC-based with an electronically balanced input and a transformer balanced output. There are already existing DIY projects based on the LA-2A and LA-3A which are wonderful. If you build one of these you won’t be disappointed. However, my goal for this project was to create a simpler and more cost-effective build that still retained the classic leveling characteristic that we love in those old designs. So I chose to start with the LA-4 circuit, and then tweak from there.

Where’s the Love for the LA-4?

Despite the almost universal love for its forebears, Urei’s LA-4 hasn’t enjoyed quite the same enthusiasm from the pro audio community. In fact, I have more than once heard it referred to as the “red headed stepchild” of the LA-2A and/or LA-3A.

Why the disrespect?

Well, the overwhelming gripe people have with the LA-4 seems to be with the signal path of a stock LA-4, not so much its dynamic behavior. Audio passing through a stock LA-4 has a tendency to sound a bit dark or ‘veiled’ while being a bit abrasive in the midrange, particularly when working with stronger signals. Both of these characteristics are a result not so much of poor design, but of the proliferation of the less-than-stellar RC4136 quad opamps that make up almost the entire signal path.

The lackluster 4136 lowered production cost and simplified the build, but it also limited the speed of the audio (called ‘slew rate limiting’) making signals dull. The remedy for this is a switch to better opamps, which is a challenge given the unique pinout of the 4136. But we’re talking an entirely new, ground up DIY project here, so opamp selection isn’t a problem for us... we can use whatever IC’s we want!

Upgrading the opamps reveals the gain reduction circuit's refined, vintage dynamic character for which classic optos are coveted. My first prototype coupled my own electronically balanced input stage with the LA-4’s original output circuit (with modern substitutes for the actives), and it sounded great. I have since swapped the output stage for the proven output arrangement I used in the EQP5 Passive Equalizer. So this unit’s signal path offers the same, exceptional performance as that in the EQP5 including the option for the vintage discrete opamp/transformer output bundle to give it more old-school love!

Expanded Feature Set and Functionality

We've added or improved features compared to the LA-4 design, including sidechain HPF, better stereo linking, a legit, discrete opto cell (instead of the off-the-shelf vactrols that everyone else is using). I will cover all of that and the path we took to get here in a future post, but our immediate need is for feedback from you regarding the possible inclusion of one specific feature.

Question for you: Wet/Dry Mix?

I must admit this feature, included on the prototypes, has become a personal favorite of mine, but one that some may feel doesn’t really belong on a compressor of this heritage—the ability to do parallel processing. It seems more and more hardware and software dynamics processors these days offer on-board parallel functionality, but is this because people find it really useful, or just because it gives marketing something to boast about?

The beauty of the LA-4 sidechain is that it excels at leveling audio signals in a musical, but not overly heavy-handed way. Yet I find that this musical sidechain, when slammed hard, does, indeed, have an attitude of its own that blends well with many unprocessed signals to affect both the perception of size as well as really sticking a signal dynamically “in your face." Under mild-to-moderate processing (which is not uncommon for such a true leveler such as this) the usefulness of parallel processing is less obvious, but when you really wind it up the process can be quite magical.

So this, dear readers, is the primary question we are struggling with regarding the design of the OLA5: should we include parallel functionality, or should we simply respect its classic heritage and stick to purely serial processing?

What do you folks think? We've included some samples and clarifying info below. And please feel free to comment or make suggestions on any other aspect of its design too. It’s not too late to change things, and we wanna know your thoughts!

Rock Mix Samples

- Dry - Unprocessed

- Series - Uses substantive, but gentle series leveling

- Parallel - Uses a slammed signal underneath the dry signal to fill in the gaps and make the overall blend bigger and fuller

- Just the crushed part of the parallel compression

Guitar and Vocal Samples

Why Two Knobs for Wet/Dry? In the original prototype I used a single ‘blend’ knob that adjusted the balance between the unprocessed and processed signals, but I found that I couldn’t quite tweak its ballistics to my liking — everything from about nine o’clock to three o’clock on the pot sounded remarkably similar with only the outer throws of the pot yielding much perceived control over the balance. This really bugged me in use, so I switched gears and chose a separate fader for the “dry” input signal just like the processed signal has. While this is a different approach to a blend knob, I find it quite simple to make the desired adjustments, and both knobs provide a proper feel. Plus, those who aren’t interested in parallel processing can simply turn the dry signal all the way off.

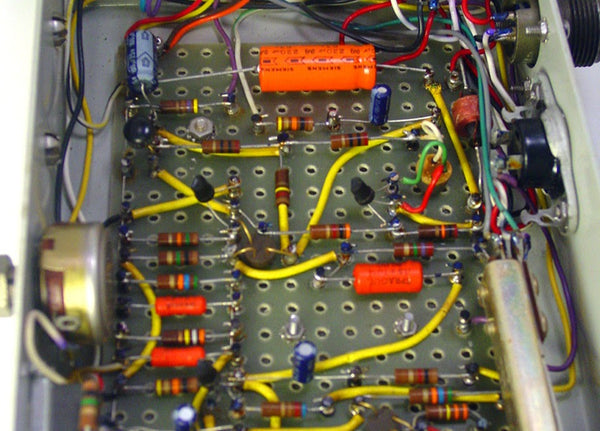

"Explain Like I'm 5": Printed Circuit Boards December 1, 2016 13:23

What is a printed circuit board (PCB)?

Before I answer that, let's talk about how circuits were made without PCBs. Before the advent of PCBs, people soldered components and wires right to each other, usually with the help of some sort of rigid board. For example, the technique shown below is called "turret board," where wires and parts are soldered to each other and to turrets to complete a circuit.

As you can see, assembling electronics used to take a lot of time, skill, and focus! Then PCBs came a long and made everything a easier by building all those wires right into the board itself.

PCBs are rigid boards with pre-wired circuitry, plus some extra perks like soldermask and silk-screening (more on those to come). So these days, instead of painstakingly cutting, bending, and soldering each connection, the assembler just has to solder each component in the right place and the PCB does the rest.

What are PCBs made of?

PCBs are made of several layers, like an onion parfait. These layers are: substrate, copper, soldermask, and silk screening. PCBs can have several of each of these layers, but most audio PCBs are "two-layer" boards (top and bottom) with this makeup:

Let's take a look at a very simple PCB, our L2A Passive Re-amplifier, layer-by-layer. To keep things simple, we'll only show the top copper, soldermask, and silk-screen layers.

The core of a PCB is fiberglass. Its job is to be rigid (to hold the parts in place) and non-conductive (so electricity won't pass from one side of the PCB to the other). The holes you see in the substrate are for mounting components to the PCB.

This is where the circuit happens. The copper circles you see are called "pads"; this is where the parts get soldered to the board. The lines are called "traces"; this is what carries the electricity from one part to another. There are only a couple of traces visible here because most of them are on the bottom side of this particular PCB.

Although the pads and traces are made of the same thing, we only want to solder to the pads. So we cover the traces in a layer of polymer called "soldermask" that keeps us from getting solder on the traces.

Finally, we print some silk-screened labeling so that the humans can know where to put the parts.

Can I make my own PCBs?

Yes! Start by learning your way around an ECAD (electrical CAD) program. The most popular free programs are EAGLE, DipTrace, Upverter, and KiCad. My favorite of the bunch is Diptrace, though EAGLE is somewhat of an industry standard among DIYers. Here's what the L2A board looks like in DipTrace:

The best beginners' guide I've found to PCB layout is Dave Jone's PCB Design Tutorial (PDF).

Once you've got a layout, you can either order your PCB from a manufacturer, or etch your own at home.

OSHPark is an amazing, game-changing service that charges only $5 per square inch for three copies of your PCB. Unless you plan to make lots of PCBs at home, you won't beat that price rolling your own, and you certainly won't approach the same quality.

If you just love the idea of making your own PCBs or can't wait for OSHPark to deliver, Make Magazine has a great rundown of all the ways you can roll your own.

Any other questions about PCBs you like me to answer?

Let me know in the comments!

Troubleshooting Audio Electronics in 3 Steps (Without Any Test Equipment) October 31, 2016 13:48